Pine Creek Power is the technology partner of Mine Energy Solutions in the Americas. The Dual Fuel mine truck technology uses multi point direct injection on individual cylinders for a precise CNG and Diesel fuel mix, using a unique control architecture and advanced fuel detonation algorithms. The control architecture does not interfere with the underlying OEM truck control systems, allowing OEM ECU updates that are transparent to the control system, ensuring 100% forward compatibility.

Diesel Displacement

of Up to

85%

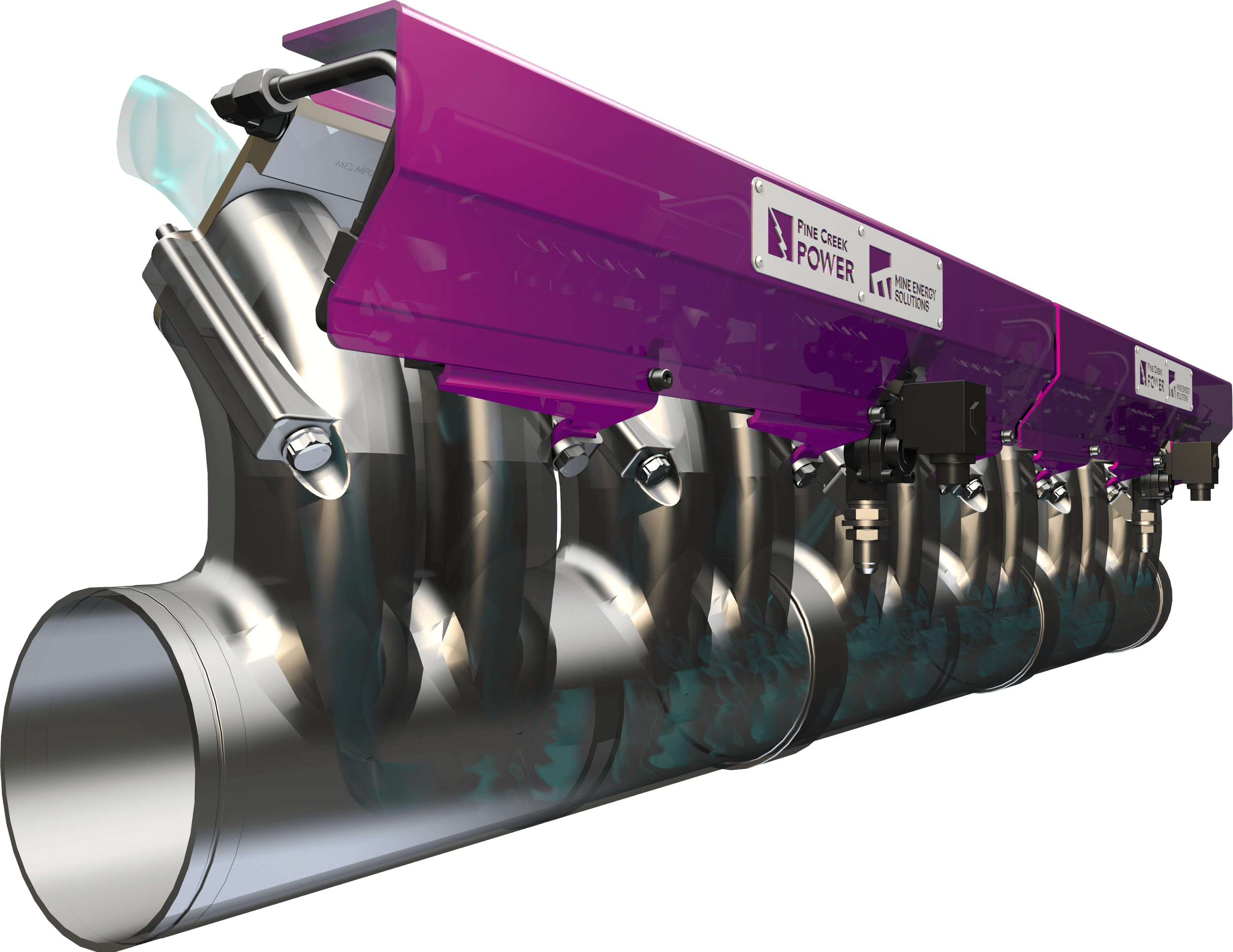

Key elements of the non-invasive dual-fuel engine technology

- OEM Diesel Injection hardware untouched

- No software changes required to the OEM engine controllers.

- OEM updates can be continually applied to the engine.

- Electronic system control architecture is designed agnostic of OEM systems.

- Custom electronic hardware and software developed and implemented to take individual diesel cylinder fuel injector requests and map this to requested fuel flow.

- System takes direct control of the diesel injector enabling variation of timing and also additional multi-fire as required.

- System uses multiple commercially available precision CNG injectors to create an accurate per cylinder, narrow injection width, gas injection system.

- System has adaptive knock control/monitoring with one acoustic sensor per two cylinders.

- System monitors exhaust port temperature to establish trim levels for diesel injector turn down.

- Fuel rail systems are non-invasive and no OEM castings are modified. Injection is via custom injector plates inserted between the inlet manifold and head.

40% *

Fuel

Savings

80% *

Fewer

Diesel

Particulates

20% *

Fewer

Greenhouse

Gases

* Ranges are Up To precentages under specific conditions

Compatible Trucks

Additional trucks currently under test and development.

Tri-Fuel

In 2022, Mine Energy Solution (MES) is releasing their Tri-Fuel system that blends up to 20% Hydrogen into the fuel mix with CNG and Diesel to further reduce mining fleet emissions.

View Announcement